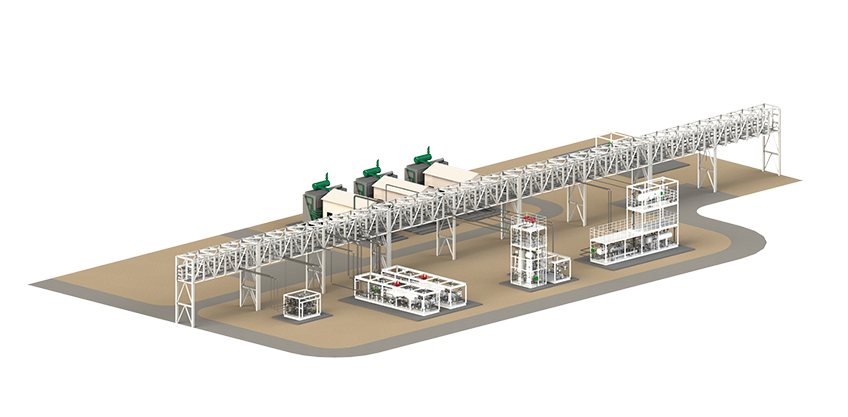

Field gas treating unit with storage and transportation system

Expected natural gas yearly yield: 128,10 ... 21,29 mmscm/year.

Operation scenario: Continuous, 8760 working hours a year.

Scope of contracted works: Concept design, detailed design.

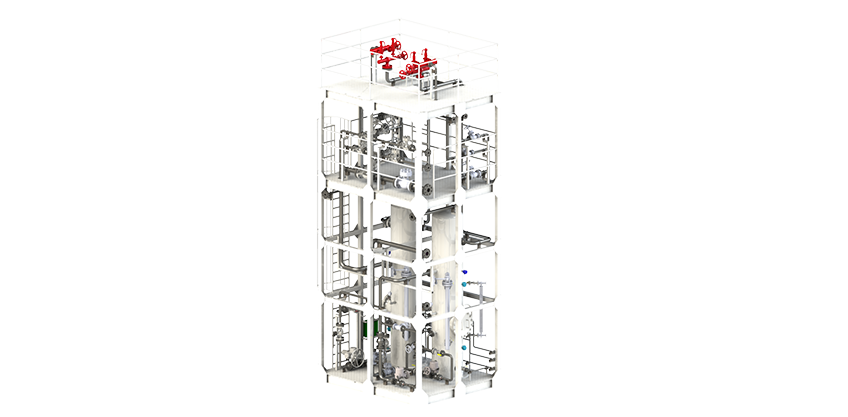

The Field gas treating unit will be supplied as a set of preassembled modules, skids, manifold assemblies and substructures. All of the process modules do not require any additional housing structures, are to be installed to an open area inside the production field and are operated at ambient temperatures ranging from minus 35 to plus 44 °С. The Field gas treating unit requires the area it is installed to be compliant with 2 class explosion proof categorization.

Process description

Field gas treating skid (FGTS) is designed to treat the gas yielded at the STO Gazprom group of production fields

A source for the FGTS is the natural gas yielded by the wells at the three fields in the abovementioned group. The process of treating the gas from these gas and gas condensate fields is based on low-temperature separation (LTS) and implies dehydration of the gas and removal of mechanical impurities from it as well as the extraction of gas condensate and layer water, to condition the gas prior to feeding it to OAO Gazprom pipeline main.

There are several process modules that make up the FGTS that are supplied as pre-assembled skids:

- Inlet tail-gas module

- Liquid slug-catcher module (2 pcs.)

- Low-temperature separation module

- Heat exchanger module

- Condensate separation and stabilization module

- Fuel gas treatment module

- Compressors

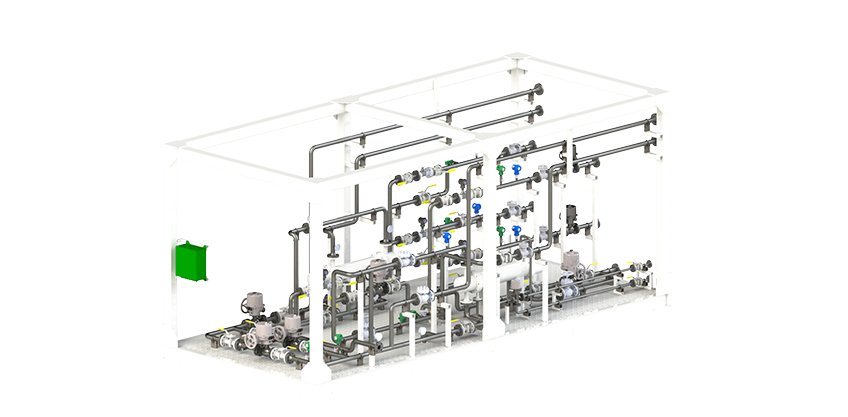

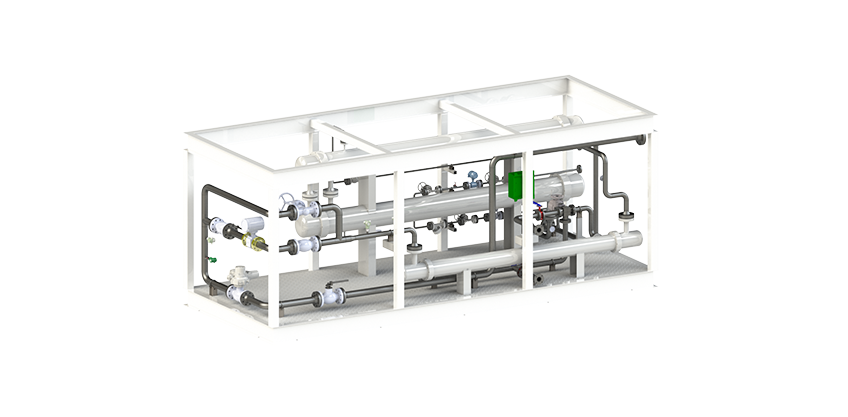

Fuel gas treating module

Fuel gas treating module is design to utilize the gas coming off the condensate separation and degassation module as the fuel gas for consumption by the plant. It may also serve to treat a portion of the dry stripped gas (pressure reduction and heating up) product.

Condensate separation and stabilization module

Condensate stabilization module produces stable hydrocarbon condensate by degassing it to the specifications compliant with GOST R

Compressors

Compressors purpose is to boost the pressure of the gas coming off the inlet separator module up to the operating pressure of the low-temperature separation module. It is required in scenarios where the wellhead pressure of the gas falling below 10.0 MPa(g).

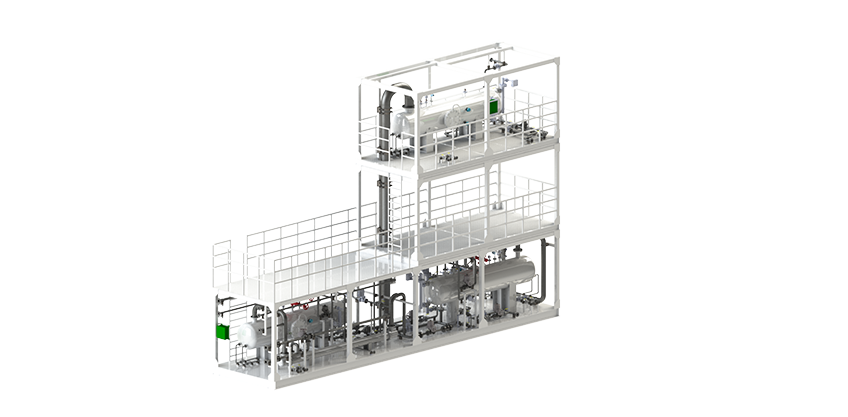

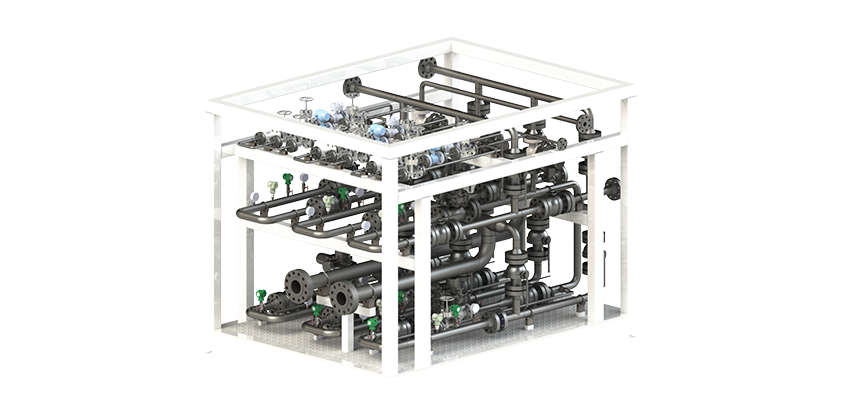

Low temperature separation module

Low temperature separation module is where the main gas treating process takes place. Low-temperature separation method is used , providing the treated gas with the specifications required by the STO Gazprom

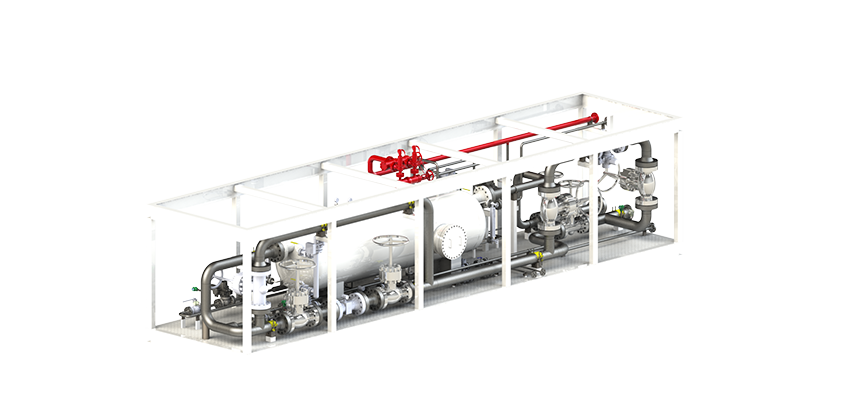

Liquid slug-catcher process separator module

The separator uses the gravitational force to separate the incoming gas condensate stream into gas, condensate and water-methanol fractions. Water-methanol fraction is separated out of the liquid collection nozzle in the lower part of the separator. Gas fraction passes through drop-collection separator on its way out in the upper part of the separator, downstream of which it is directed into the low-temperature separation module at its operating pressure of at least 10 MPa (g). Unstable condensate fraction is extracted in the separator and upon reaching a certain level, programmed in the level controller, is directed through a back valve to a condensate separation module for an initial degasification at 2.0 MPa(g).

Heat-exchange module

The module comprises two heat-exchangers:

- recuperative “Gas — Gas”

- “Gas — Trietheleneglycol” heat exchanger

Recuperative heat exchanger is designed to recuperate heat when treating the gas with the low-temperature separation process. “Gas — triethyleneglycol” heat exchanger in turn is designed to heat the treated gas. Methanol injection is provided upstream of the gas to be cooled.

Inlet tail gases module

Inlet tail gases module role is to receive the incoming source gas from the field’s wells, to reduce its pressure where necessary, to inject hydrates catchers (methanol) into the stream of gas upstream of reducing the gas pressure and to direct the flow each portion of the gas to the corresponding downstream processing module for required treating. It also separates the liquid from the saturated source gas, catches the liquid blobs from the gas stream and separates the liquids into condensate and water-methanol mixture.