Methanol regeneration

General description

The main purpose of the methanol regeneration unit is to restore high-concentration methanol (95% mass) from the water-methanol mixture.

Methanol is mainly used fir hydrate inhibition. Its low ice formation temperature allows methanol to be used in a wide range of temperatures and pressures.

Growing methanol prices make regeneration process economically efficient even in small scale.

Process description

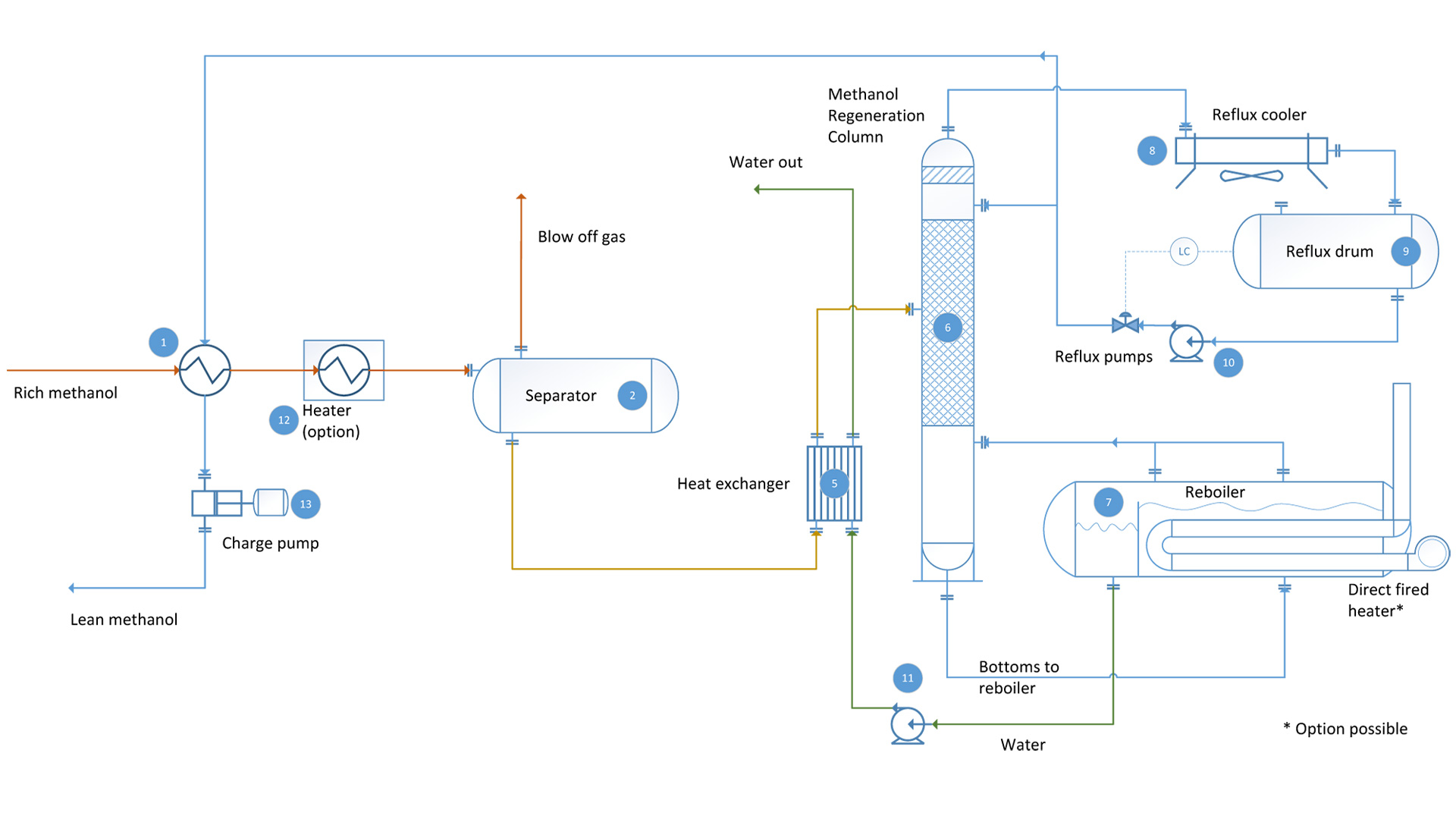

Rich methanol through the pre-heat heat exchanger (1) flows to the

From

Being heated by the stripped water from the reboiler in the heat exchanger (5) rich methanol enters regeneration tower (6).

Heat required for the regeneration process is supplied form the reboiler by direct fired heater, steam of thermo electric element. Condenser (8) provides the reflux stream

Reflux pumps (6) return methanol back to tower while the balance of the methanol stream is pumped toe the lean methanol storage.

Key benefits

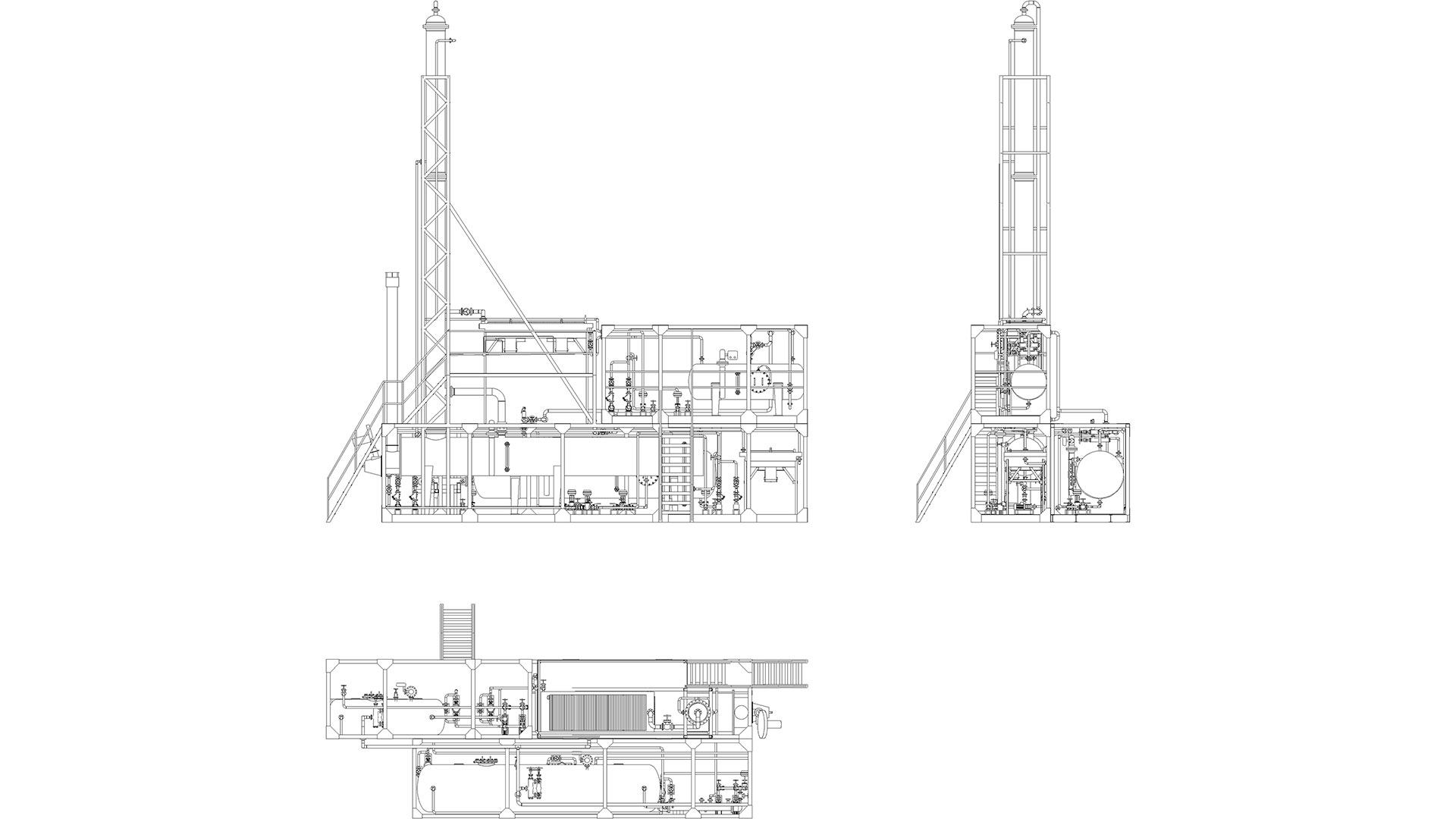

- Skid mounted design

- High efficient

3-pase separator in standard design. Modern coalescing elements provide efficient phase separation resulting low hydrocarbon pollution of the methanol - Build in solutions for scale prevention

- Separate weir section for HC accumulation with automatic level control

- Stainless steel condenser tubes and distillation trays

- 87% heat efficiency (with forced draft burners)

- Quick opening closures for filter replacement